Little Known Questions About Sheroz Earthworks.

Little Known Questions About Sheroz Earthworks.

Blog Article

Our Sheroz Earthworks Diaries

Table of ContentsAll about Sheroz EarthworksThe Main Principles Of Sheroz Earthworks How Sheroz Earthworks can Save You Time, Stress, and Money.The Definitive Guide for Sheroz EarthworksThe Definitive Guide to Sheroz Earthworks

For any kind of earthwork contractor, it is crucial to do deal with top quality, precision, and on time. Using device control in work equipments enables enhancing the different phases in the earthwork process, from planning to the upkeep phase - topcon laser levels. The device control system helps the device driver in attaining the target plane promptly and quickly

The maker control system guides the operator with centimeter accuracy. Remote support conserves time and cash, as it minimizes downtime in jobsites.

The Single Strategy To Use For Sheroz Earthworks

Added training and instructions are constantly available over remote support when required. The earthmoving sector has actually utilized our field-proven remedies since the early 1990s. Our system's elements are meticulously designed to stand up to the harsh conditions of building and construction websites. Comparison of the very same job executed making use of equipment control versus the standard approach reveals that, generally, the traditional approach requires 50% even more time to complete the exact same job as the technology-assisted method. https://pblc.me/pub/2669cbf4eae9a6.

Go into the Xsite machine control system; it's here to give you with a significant benefit when working with earthmoving machinery. Discover exactly how Xsite Equipment Control can improve your performance and make sure job security! Xsite Equipment Control systems can be installed to any type of excavator from mini excavators to large mining excavators.

How does equipment control work? In 2D systems, the maker is equipped with adjusted disposition sensors.

The system is very easy to learn the essentials can be shown in under one hour of training. Exactly how does the remote assistance work? A wireless internet link makes it feasible to establish a remote connection between the maker control system and the solution.

How Sheroz Earthworks can Save You Time, Stress, and Money.

What kind of information styles Xsite systems assistance? Xsite Machine Control systems sustain open conventional data formats, making it possible for seamless details circulation from one system to one more. Supported file styles: 2D-Maps: DXF Factor files: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Versions: DXF, XML What parts are mounted on my device? Relying on your option of system (with or without positioning, i.e - trimble gps., 2D or 3D), your equipment is outfitted with inclination sensing units, a controller device, and a display/operating panel.

Several hardware and software options exist to help establish an equipment's present position on the planet and compare it with a wanted design surfaceand building operators can do more to take advantage of the advantages. Maker control is making use of different positioning sensing units and a display to offer the operator with a referral between the position of the pail or blade and the target quality.

Depending on the arrangement, maker control systems can offer the driver with an easy visual guide to bucket or blade setting, or can instantly relocate the blade to quality by talking with the device's hydraulics - https://www.domestika.org/en/floydoverbeck4500. There are machine control systems readily available for almost any kind of device: graders, dozers, excavators, soil and asphalt compactors, scrapers, trimmers, milling devices, and pavers

The Single Strategy To Use For Sheroz Earthworks

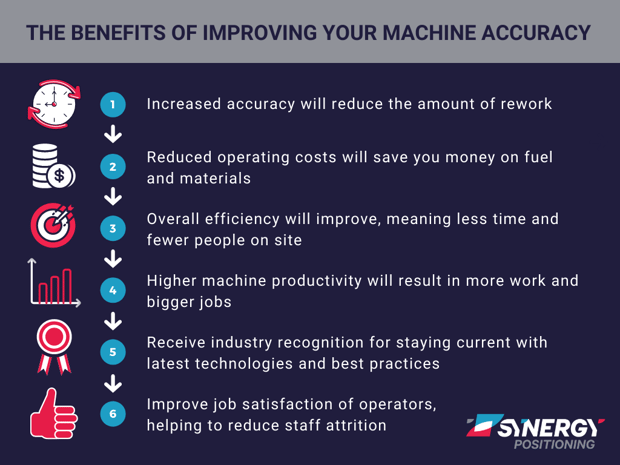

Machine control can additionally help raise performance and lower overall costs. Building devices without machine control will end up being a point of the past and the benefits got from it will certainly be various.

Trimble maker control systems give a myriad of benefits to anyone who uses earthwork machinery and, at EarthCalc, we can provide you with 3D files for your maker control-enable tools. Unsure if maker control is worth the expense? Consider the following reasons that you need to consider this option.

Using general practitioner aligned with your 3D style data, these systems basically guarantee that you will certainly eliminate or position the right amount of product at the building site. On the majority of building websites, remodel is a typical and discouraging fact, however this post with Trimble equipment control, you can eliminate the requirement for rework.

Not known Details About Sheroz Earthworks

Commonly, with Trimble device control, you can remove excess equipment at a particular work website. A work that might have called for the usage of three or 4 pieces of excavating devices currently could require only 2 items of devices to achieve the same job in much less time. This allows you to move your tools to one more task site and take care of multiple jobs at once.

Report this page